Routine Checks Ensuring Equipment functionality are paramount for maintaining operational efficiency and preventing costly equipment failures. A well-defined and executed routine check program is essential for any organization reliant on machinery or equipment. It’s not just about checking a box; it’s about proactive maintenance, preventing unexpected breakdowns, and maximizing the lifespan of your assets. This thorough guide outlines a structured approach to routine checks, focusing on determineing potential problems early and improving overall equipment performance. This article will define routine checks, explain their importance, and offer practical steps for implementing a robust program. We’ll also discuss the various types of checks needed, the frequency, and the key performance indicators to track. Finally, the importance of training and documentation for a achievementful program will be highlighted.

Defining Routine Checks

Understanding the Importance of Routine Inspections

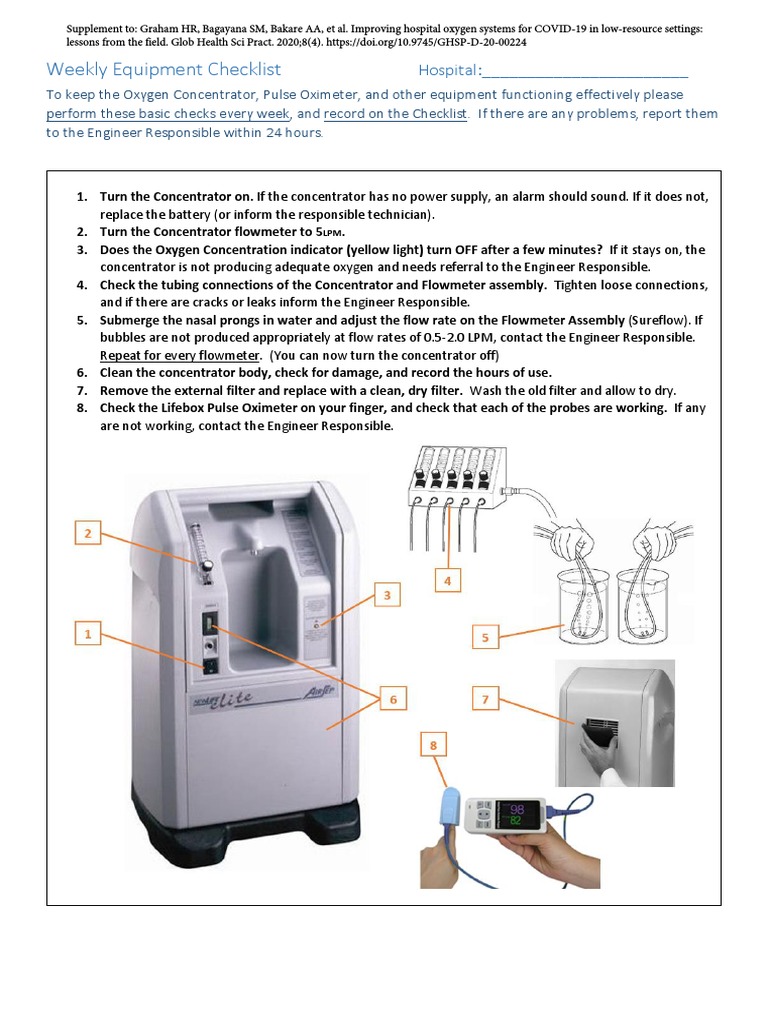

Routine checks are systematic inspections and tests performed regularly on equipment to determine any potential issues before they escalate into major problems. These checks can scope from simple visual inspections to more complex tests, depending on the equipment and its criticality. Regular checks are vital for maintaining the reliability and safety of machinery. A thorough approach to routine checks addresses the entire operational lifecycle of equipment, from initial setup to final decommissioning. For example, an initial setup inspection may involve checking alignment and lubrication, while periodic inspections may include functional testing, safety checks, and detailed diagnostic evaluations. Consistent routine inspections enable proactive maintenance, reducing the risk of costly breakdowns and minimizing downtime. Proactive maintenance is far more cost-effective than reactive maintenance, focusing on preventing problems from occurring in the first place.

determineing Potential Problems

Analyzing Equipment Components and Systems

Equipment failures often stem from overlooked issues. Regular checks allow for early detection of minor problems that can lead to more serious damage over time. This approach is vital for avoiding major breakdowns, which can outcome in significant financial losses and potential safety hazards. Common causes include wear and tear, misalignment, loose connections, or inadequate lubrication. Through thorough checks, these problems can be identified early, allowing for timely repairs or replacements. For instance, a simple visual check of bearings can reveal signs of wear, enabling timely replacement before the bearings fail completely, preventing potential catastrophic equipment failure. Properly documented routine checks offer a valuable historical record, helping to predict future maintenance needs and optimizing maintenance scheduling.

Establishing a Robust Check Program

Implementing a Structured Approach

A structured approach to establishing a routine check program is essential. This includes defining clear responsibilities and procedures, creating a check-list for each piece of equipment, and setting a consistent schedule for inspections. Furthermore, the program must include provisions for documenting findings, both positive and negative, and for communicating maintenance needs. The program should also include a method for tracking the findings, allowing for trend examination and the development of preventative maintenance strategies. A well-structured program not only helps determine issues quickly but also reduces the potential for human error by standardizing procedures. This structured approach can be a critical component of improving overall safety in the workplace.

Monitoring Key Performance Indicators (KPIs)

Tracking Equipment Health and Performance

Monitoring key performance indicators (KPIs) associated with equipment performance and reliability is crucial. This includes tracking downtime, maintenance costs, and overall equipment efficacy (OEE). These metrics help determine areas requiring attention and offer data-driven insights for continuous improvement. By regularly tracking these KPIs, organizations can evaluate the efficacy of their routine check programs and make necessary adjustments to improve overall equipment performance. A significant reduction in equipment downtime can translate to substantial cost savings for an organization. For example, tracking hours between breakdowns can allow for proactive scheduling of maintenance and avoid prolonged periods of equipment downtime, demonstrating the efficacy of the program.

Related Post : Tech Solutions Simplifying Remote Health Monitoring

Utilizing Technology for Efficiency

Leveraging Tools for maximized Maintenance

Utilizing technology can greatly improve the efficiency and efficacy of routine checks. Software and mobile applications can streamline scheduling, documentation, and reporting. Digital tools can offer real-time data on equipment performance and alert personnel to potential issues, enabling a more proactive approach to maintenance. For instance, sensors on machinery can offer real-time data on vibration, temperature, and other critical parameters, allowing maintenance personnel to determine potential problems before they lead to breakdowns. The use of technology in routine checks can be instrumental in significantly reducing unplanned downtime and improving the overall operational performance of an organization.

In conclusion, routine checks are critical for maintaining equipment functionality and preventing costly downtime. By implementing a thorough routine check program, businesses can maximize equipment performance, improve safety, and reduce maintenance costs. Prioritize these checks for optimal efficiency and ensure your equipment stays in peak condition. Schedule regular maintenance, invest in proper training, and consider using predictive maintenance tools to further enhance your equipment management strategies.